It’s just five weeks from the start of big league spring training…and opening weekend of the the college baseball season. And for those in the business of ‘wood’, at the Phoenix Bat Company, the first fragrance of spring comes in ash, birch, and maple.

My former Piqua High School teammate, and fellow pitcher, John Hinsch called me recently and asked, “Hey, how would you like to come over to Plain City and take a tour of the plant? Maybe see the production process?”

Well, those that know John (aka Scott) might be surprised to hear that he wasn’t talking about the production of money, or business capital. Because since graduating from Indiana University in 1974 Hinsch has been in the banking business, where he’s built a fine career.

No, about three years ago he bought into the Phoenix Bat Company, in Plain City, producer of fine wooden baseball bats for every level of baseball – the big leagues, the college summer leagues, and serious high schoolers – and even ceremonial and presentation (or trophy) bats to commemorate a special accomplishment, season, or career. Gift bats, if you will. If it’s wood, with a barrel at one end and a knob on the other, Phoenix makes it.

But they also make variety of other wood products – ‘mega’ golf tees, night sticks, and a wide assortment of novelty gift ideas for the average sportsman.

I eagerly accepted, because in truth…the start of the baseball season is just five weeks removed with big league spring training, and the college season kicks off the weekend of February 16th. And Press Pros, through the support of Phoenix Bats, will bring you coverage of the Ohio State Buckeyes and the Dayton Flyers.

Of course, there’s a great story idea with all this, because it is fascinating to tour the Phoenix plant and observe how they take a piece of ash, maple, or birch, put it on a computerized lathe, and within minutes it becomes a baseball bat made to exact length, weight, and comfort of grip.

Of course, there’s a great story idea with all this, because it is fascinating to tour the Phoenix plant and observe how they take a piece of ash, maple, or birch, put it on a computerized lathe, and within minutes it becomes a baseball bat made to exact length, weight, and comfort of grip.

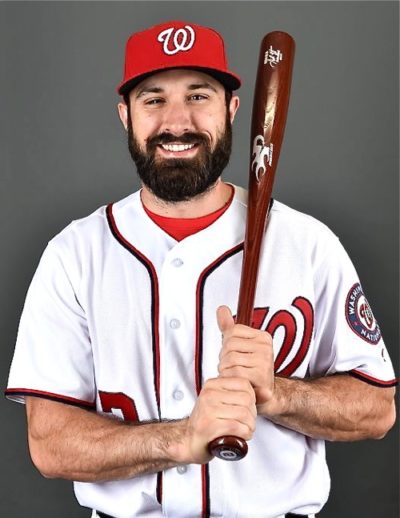

And lest you think that all baseball bats are essentially alike, think again. Or, ask a professional baseball player, as we did with former Texas Ranger Jared Hoying, from Fort Loramie, Ohio, who just recently signed a contract to play for the Hanwha Eagles, in South Korea.

Hall of famer Ted Williams used to tour the Louisville Slugger plant in the off-season to personally pick out the bats he wanted for the coming season. And rumor was Williams could tell just by feel if the weight of a particular bat was off by an ounce, or if the grain was less than up to his personal standard.

Former Texas Ranger, now playing in South Korea, Jared Hoying.

“There is a difference,” says Hoying. “Me, I take the barrel of the bat, hold it up to my ear and give it a thump with the palm of my hand. If it makes a ‘ting’ sound it’s harder and a good piece of hitting wood. If it makes a ‘mushy’ sound you don’t want it.”

And as type of wood?

“Most of the big league guys use maple, because it’s harder than ash,” adds Hoying. “But some guys are using birch, because birch actually breaks in as you use it. The longer you hit with a birch bat the harder and more compact the grain becomes…so they usually last for a while.”

And size?

“For me it has to be 32 ounces in weight and 34 inches long,” says Hoying. “I’ve been using a skinny handle and a big barrel because it’s easier to whip through the strike zone.”

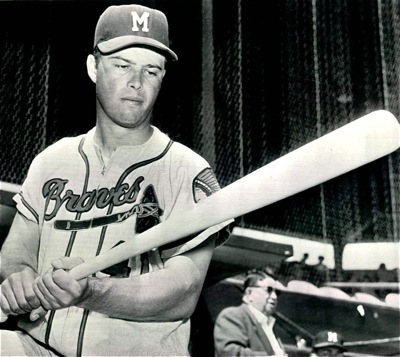

Baseball players are legendarily finicky about the exacting qualities of their bat – sometimes to what seems a fault. Milwaukee Braves third baseman, and hall of famer, Eddie Mathews once hit a home run 475 feet in the old Polo Grounds, in New York, and then picked up his bat after he touched home plate and promptly broke it in half over his knee. Home run or not, it just didn’t feel right to Mathews.

But they make bats that feel right at Phoenix…to the exact specification of big leaguers like Washington Nationals outfielder Adam Eaton (from Kenton Ridge High School), and Houston minor league slugger Ronnie Dawson, who signed with the Astros after his junior season at Ohio State, two years ago. And they make them, as Eaton points out, just the way he likes them.

Hall of famer Eddie Mathews had 512 career home runs, and was finicky about the quality and feel of his bat. After hitting a 475 foot home run one day he touched home plate, picked up his bat, and broke it over his knee, because…it didn’t feel right!

“I’ve been swinging Phoenix wood bats since I was in the junior high,” says Eaton, in his second year with the Nationals. “There are bigger bat companies, but for me the quality of their product, plus the individual attention they give to people, is what makes them stand out. You can give Phoenix a rush order and you know the quality is still going to be the same.”

Phoenix bats come in traditional ash, in maple, and in birch, and Eaton maintains that quality is the reason he’s still swinging their product.

“It’s the tool I use to make a living,” he says. “I’ve tried other bats for different reasons, but my day-to-day bat is Phoenix…because I just like the distinctive feel of their bats.”

And like Hoying, he has his own way of determining the quality of a particular bat.

“I still like traditional ash because it has a bit more give to it, but I don’t use my hand to tell how hard the grain is. I just tap it against my head.”

Other knowledgeable baseball people have claimed they can tell the quality of a baseball bat by smelling the wood. The harder it is, the less aroma it emits. That’s extreme, of course, and difficult to prove, but whatever it takes to make the end user confident in their tools, as Adam Eaton puts it…Phoenix is willing to accept.

“The point is,” says Phoenix president Seth Cramer, “we want to make the very best bat possible. So we have the most advanced machine in the word at Phoenix to make the most precise bat in the world – right here in Plain City, Ohio.

Thousands of wood billets in the Phoenix inventory – every one is graded for weight and quality.

“We’ve had it since 2004 and it’s still the most advanced machine in the world – better than the machine that little company down in Kentucky (Louisville Slugger) uses. Attention to detail matters, at every level of our product, but especially for the professional player, like Adam Eaton. They use our product to make their money, but we give every order that added bit of attention. We want to ensure that every customer has the proper wood and the proper weighted bat for their game.”

And to ensure that, production manager Joel Armbruster is hands-on with the day-to-day process of turning out Phoenix bats.

From literally thousands of wood billets in their inventory of ash, maple, and birch, Armbruster selects and supervises the lathe cutting and sanding process. Then bats may be dipped in a clear-coat lacquer to ensure additional hardness, painted (if specified), and then sent to dry. Inspection is rigorous, and continual, until orders are boxed and shipped.

And Phoenix bats are shipped all over the world to service every level of baseball, from the most exacting professional, to the aspiring high schooler, and to collegiate prospects who use them in summer leagues.

At Ohio State University, the Buckeyes recently purchased a shipment of Phoenix bats for off-season training.

Why?

“They give our players a better sense of making contact on the ‘sweet spot’ of the bat,” says head coach Greg Beals. “We use aluminum bats in games because for the sake of having an equal competitive advantage (all NCAA teams choose to use aluminum), but aluminum doesn’t have the ‘feel’ of wood. Wood helps our hitters develop a better sense of bat control, and a feel for that ‘sweet spot’. The kids enjoy hitting with wood.”

Washington Nationals outfielder Adam Eaton holding the tool of his trade…a Phoenix bat.

But Phoenix naturally markets to a growing list of professionals who, like Eaton, claim they just like the feel of a Phoenix bat.

“It varies from year to year,” says Brad Taylor, Phoenix’s manager of professional baseball accounts. “Right now the number of major and minor league players under contract is going to grow in the coming weeks as spring training draws closer. But last year I think we had about 40 different players swinging our bats.”

But back at the lathe I asked Joel Armbruster about the ‘smell’ of a baseball bat, that familiar fragrance of wood under the shaping pressure of a steel knife and a sanding collar. He smiled appreciatively from the experience of having made thousands of them, recognizing the attributes and even the aroma of each different wood – ash, birch, and maple.

And in the real world of baseball – warm weather and hope that springs eternal – that experience and appreciation is less ethereal and more cognitive as players of every age once again pick out their bat and give it the once over, each with their own personal assessment.

Some with go on weight and feel, like Ted Williams.

Some with go on weight and feel, like Ted Williams.

Others will thump their palm against the barrel, looking for that ‘ting’ – or tap it against their head to gauge its hardness.

And as to the smell, only Ted Williams and Eddie Mathews probably knew for sure, and they ain’t talkin’ these days. But likely, if you’re that into it you’d smile to see a billet of ash on a Phoenix lathe, which does create a familiar aroma of spring – of wood, baseball, and life with a better, predictable meaning.

Hope springs eternal for another season, another year. It’s as familiar as the crack of the ball against an Ohio-made bat.

A ‘Phoenix’ bat!

The chips fly….”The most advanced machine in the world is used at Phoenix to make the most precise bat,” says company president Seth Cramer.

Bats for every league and every occasion – Phoenix is proud to sponsor Buckeyes baseball on Press Pros.

Production manager Joel Armbruster inspects the lathe process on a new Phoenix bat, in their plant in Plain City, Ohio. (Press Pros Feature Photos)